Cycling is about staying fit and using resources wisely.

Recumbent bike makers can even reuse old bike parts to make new machines – its

been very satisfying for me since about 1987!

Recently I’ve branched out to use old bike wheels in non-recumbent

things.

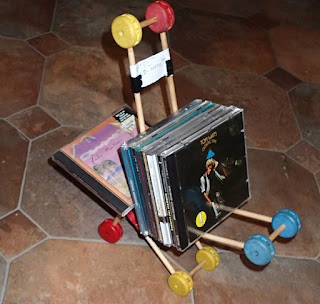

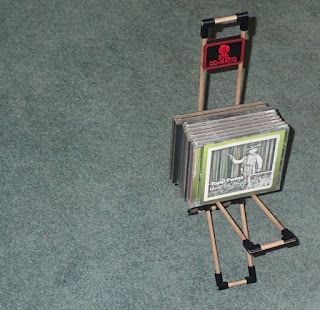

I have a 3D printer and a few years ago developed some

designs to join CDs together to make

geometric shapes (see article here). CDs are round just like bike wheels, and

so I've gone on to use CD joining techniques to make bike wheel versions of the

mathematical shapes called platonic solids. These include tetrahedrons and

dodecahedrons and I am working on a 20 sided icosahedron.

Inspiration for the shapes comes from the bike dome at Ceres

in suburban Brunswick– I don’t anticipate building anything that big and my

designs might be a bit more orderly, but the dome shows what can be done. The

Trisled newsletter recently featured a similar community-built dome at Meeniyan

in Eastern Victoria.

A few weeks ago, I gave my small tetrahedron table away to

my friend Simon for his 60th birthday and was able to transport it to his place

by bike. That was on the way to the Wecycle bike shed where we volunteer. At

his party later that evening, it was set up in his garden, staked to the ground

as its base is not very big and its prone to tipping.

A larger tetrahedron I made uses a raft of 3 bike wheels

bolted together to form a side of the 4 sided tetrahedron. I’ve had this for

quite a while and have transported it by trike and trailer. I’m not sure if it

qualifies as a road train or pantechnicon, but this is a 14 wheeled vehicle!

|

| From Heidi "Here That’s a fun story – made me chuckle. Here’s a pic from the day.

Thanks for letting me use the sculpture!

Cheers

Heidi |

Once I took it to a community bike day and it was noticed by

Heidi Marfurt who is the Darebin Council’s sustainable transport officer. Just

a few weeks ago Heidi wanted to use the sculpture at another community bike

day, The Rezza Bike Day.

The sculpture uses the wheel centres as axles for small

windmills which also use cds as blades and a 3d printed hub. That is just a fun

thing but shows what can be done with recycling. When Heidi asked me to loan

the bike sculpture I decided to extend it and worked out I could make something

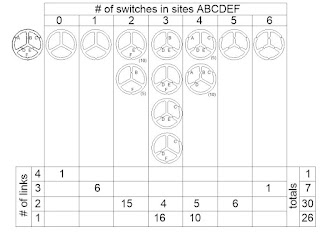

quite high (about 1.8m) without using only 6 extra bike wheels. The pattern is shown in the picture – as long

as there is part of a wheel on an edge, then the outer triangle shape can be

made, even if the outer triangle is not completely filled in. I needed 2 goes

of putting it together to get the pattern right.

Actually loading the sculpture sides into the Heidi’s car

involved Tetris-like manipulative skills and in the end only the smaller

tetrahedron would fit in. A few days later Heidi came back to my house with the

sculptures and they were festooned with ribbons and a couple of the CDs had

broken off. I was thinking it's a bit like those stories where a garden gnome

gets kidnapped and sends postcards from Queensland and then turns up months

later with a suntan and tattoos! Heidi was quite sick of loading and unloading

the sculpture in cars by this time, but the whole event went well and the

sculpture was appreciated.

Most recently, I used the frame for painting a crank arm on

a Wecycle repair bike. This was to turn a silver right hand crank black, as the

original black one had a stripped thread. The other hanger in the back yard is

the dodecahedron, used as my regular clothes line.

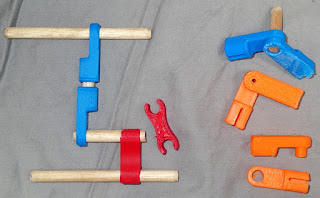

Sofar I’ve been making wheel joiners (they act as platonic

solid edges) from steel tube, pvc pipe or wooden dowel. When there’s a narrow

angle (ie on tetrahedrons), the large steel tube seems better, and the drilling

can be marked out with dividers and a centre punch. For larger angles like on a

dodecahedron, I use the dowel, and drill with the help of a 3d printed jig.

This wikepedia page

https://en.wikipedia.org/wiki/Table_of_polyhedron_dihedral_angles gives the

relevant angle between faces, it is called dihedral angle in geometry-speak.

I plan to go on building the bike wheel sculptures, and

mostly use 27 inch steel bike wheels. The 27 inch bikes are now of an age with

the are often being thrown out and are not worth restoring - or are only worth restoring if the wheels are swapped out - so they end up in

the recycling dumpster at Ceres. I can load up about 4 wheels at a time on the

back of my bike, even more if the spokes have been removed. Also I know Serge,

the volunteer who does most of the stripping of unwanted bikes at Ceres. We

stop and have a chat while I’m there, and swap notes about the Wecycle and

Ceres Sheds and our bikes.